|

| October 15, 2013 | Volume 09 Issue 39 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Aerospace: University of California Irvine's Aeroacoustic Laboratory uses DryLin T profile guides

DryLin T miniature guide rail systems from igus.

Students from the University of California, Irvine, recently used DryLin T profile rail guides donated by igus as part of The Geared Turbofan Project, designed to study the noise attenuation effects of a hybrid wing body in relation to the placement of an aircraft's turbofan. The students are part of UCI's Aeroacoustic Laboratory, which aims to study the acoustics of aerospace technologies such as fans, nozzles, ducts, and more.

This particular experiment, funded by The Boeing Company, placed a noise shield under an aircraft turbofan in order to measure the attenuation of noise in the downward direction. Traditional aircraft have a main fuselage, two large wings, and engines mounted below the wings. Most of an aircraft's lift comes from the two wings and the engines mounted below them, which are traditionally unshielded. The hybrid wing body (HWB) design, also known as a blended wing body, features a fuselage that blends directly into the wings. One advantage of this design is that the airfoil-shaped body assumes most of the lift so the aircraft can use smaller wings. The design also creates less "deadweight" surface area, which prevents the aircraft from losing lift or dragging. Another advantage, currently under study at the lab, is the attenuation in downward noise. When the engines installed above the fuselage use a noise shield, it is quieter for people on the ground.

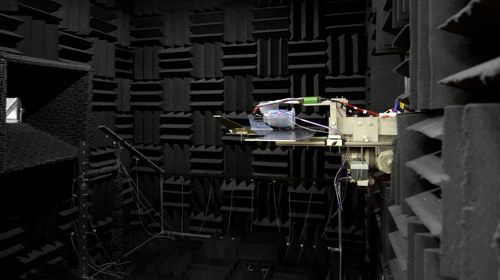

In order to study the effects of the noise shield, a small-scale model of the geared turbofan engine was built and tested in an anechoic chamber. The nacelle and fans are made using stereolithography 3D printing, and the fan is powered by a brushless DC motor, typically used in extreme-performance RC planes. To simulate the presence of the fuselage below the engines, a simple noise shield was made in the shape of the HWB planform provided by Boeing. The shield itself is made from 1/8-in.-thick aluminum sheet and is nearly 6 ft long from wingtip to wingtip in order to match the scaling of the nacelle and fan.

The shield is mounted on the DryLin T Profile Rails along with manual clamping carriages. The manual clamping carriages are bolted onto the metal fixture holding the turbofan assembly, allowing the shield to slide forward and backward in relation to the nacelle with ease.

The noise shield is mounted using DryLin T profile rail guides and manual clamp carriages. The linear guide system makes it possible to study the noise attenuation effects of the turbofan placement relative to the back end of the shield. The manual clamp carriages are bolted onto the metal fixture holding the turbofan assembly, which enables the noise shield to slide forward and backward in relation to the nacelle with ease. Unlike recirculating linear ball guides, DryLin T profile guide rails use self-lubricating glide pads that require no greasing or external lubrication. They are a more cost-effective, maintenance-free solution.

The entire assembly setup for experiments in the anechoic chamber. The objects with wires coming out of them are microphones (23 in total) capable of detecting sounds up to 120 kHz.

"The DryLin T rails and carriages withstand the torque of the heavy shield," said Tae Kim, a member of the UCI Aeroacoustic Laboratory team. "If a simple bar of metal had been used, the shield would have needed to be detached from the bar and then reattached at a different location with screws and nuts. The DryLin rail and carriages allow for easy movement of the shield, which eliminates the risk of screws falling. [It also] allows the shield to move at very small increments, which expands the scope of the study. The pre-drilled holes on the rails made it easy to mount, and the machinability of the rails allowed for easy adjustments in length."

In conjunction with the company's Y.E.S. (Young Engineers Support) Program, igus donated the DryLin T profile rail guides at no cost to the UCI students. The Y.E.S. Program aims to foster the mechanical design ideas of students with a passion for engineering, while at the same time educating them on the merits and benefits of plastic components.

To request a free sample of DryLin T, visit www.igus.com/quickorder or call 1-800-521-2747. To learn more about the Geared Turbofan Project, visit http://supersonic.eng.uci.edu/rotor_acoustics.htm.

Source: igus

Published October 2013

Rate this article

View our terms of use and privacy policy